Microbiological Safety Cabinets (also called Biological Safety Cabinets) are laboratory ventilated enclosures intended for work with biological agents including pathogenic micro-organisms; genetically modified micro-organisms; cell cultures and human or animal tissues and fluids. They offer protection to the user and the environment from aerosols arising from the handling of potentially hazardous and hazardous micro-organisms, with air discharged to the atmosphere being filtered.

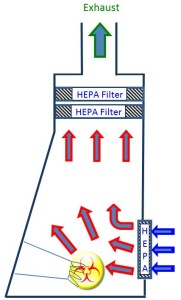

Class I Biological Safety Cabinets provide operator and environmental protection but not product protection.

Class I MSC are open fronted units which continuously draw air into the cabinet and out through a HEPA filter. They are suitable for use with hazard group 1, 2 or 3 organisms, subject to risk assessment.

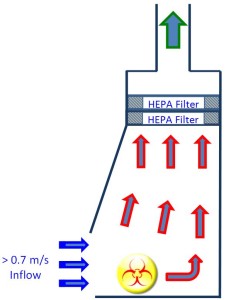

Class II Biological Safety Cabinets are the most commonly used microbiological safety cabinets. This type of cabinet is similar in design to the Class I safety cabinet, but protects the working area from external contamination as well as protecting the operator. Inward air is directed downwards and below the work surface, HEPA filtered and then redirected back into the work area as a laminar down flow of clean air. The balance of this laminar down flow with the incoming air provides an air curtain to ensure operator protection. A Class II safety cabinet is suitable for use with hazard group 1, 2 or 3 organisms, subject to risk assessment.

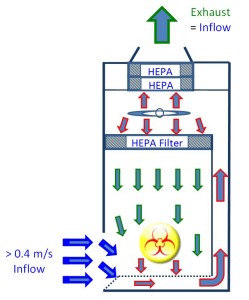

Class III Biological Safety Cabinets are totally enclosed units in which operations are conducted through gloves attached to glove ports. In a Class III MSC, air enters and leaves the cabinet through a HEPA filter. A Class III safety cabinet offers maximum operator and product protection and is suitable for work with organisms of all hazard groups, including group 4